Paper Coating and Converting research group specializes in surface engineering of natural fibre-based materials such as paper and board, as well as use of coating and printing technologies as fabrication methods for novel value-added products.

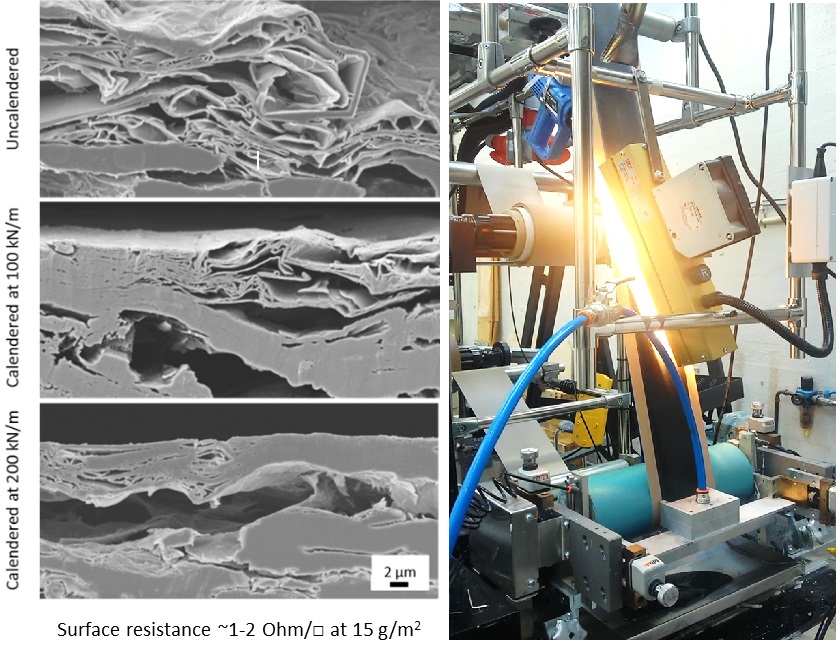

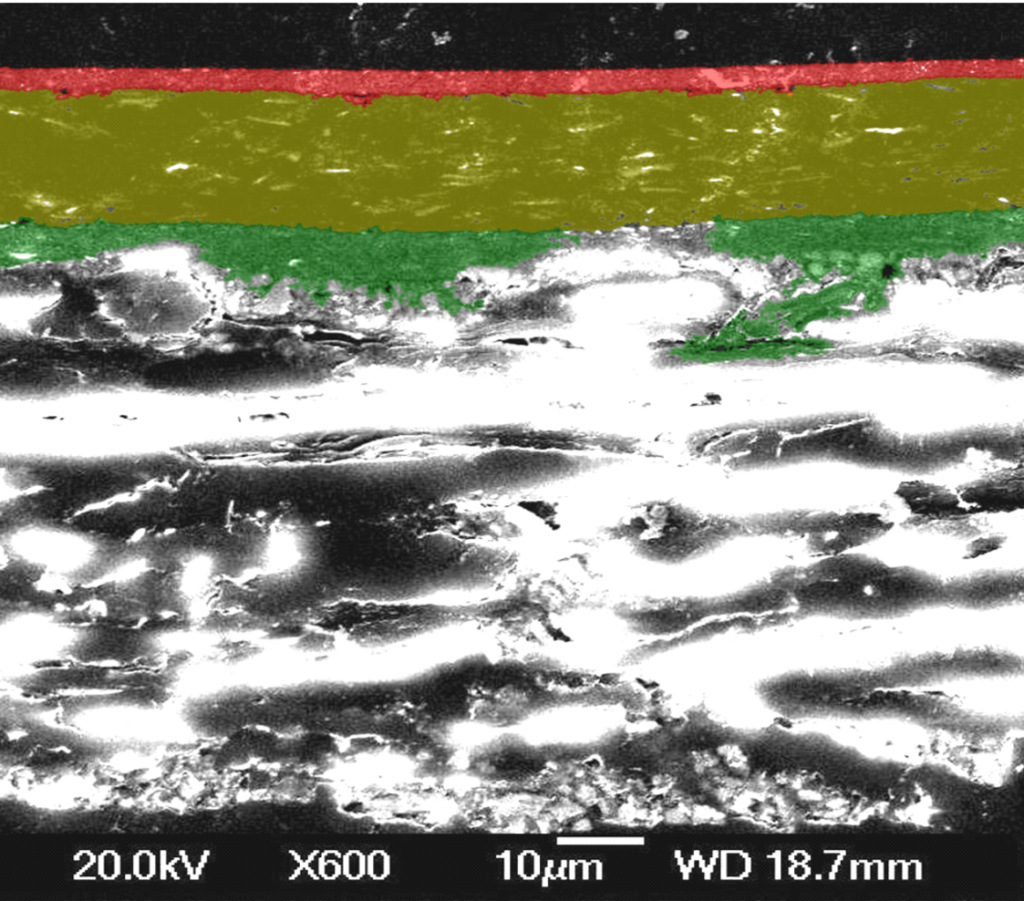

Research subjects range from traditional pigment and dispersion coating to novel surface treatment methods such as plasma coating and pyrolysis enabled nanoparticle deposition. The surface modifications of materials aim at controlling functional properties, e.g. wettability, absorptivity, smoothness, porosity, electric properties, adhesion and barrier performance, which are important for targeted end-use applications.

One of the major research areas, controlling printability of traditional graphic paper grades, is today expanded to include coating and printing of functional materials. Other research activities in this area include embedding functionality into fiber-based substrates and making them compatible with potential future value-added applications such as printed sensors, electronics, and photonics.

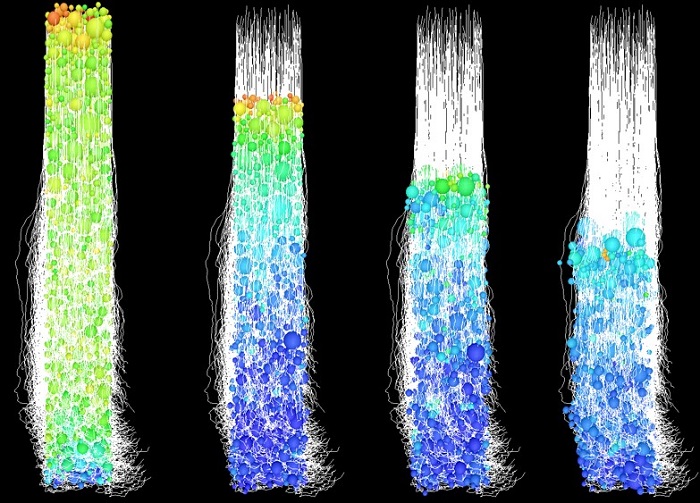

The group specializes also in mathematical modelling and numerical simulations related to coating processes, complex composites, and porous media. Contract services are offered for printing and coating in laboratory and mini-pilot scale as well as analytics for surface chemical, rheological and porous material analysis (Hg-porosimetry).

For examples of on-going research, see the doctoral students’ projects:

Kofi J. Brobbey: Nanostructured Large-area Antibacterial Surfaces (nLABS)

Deepika Dahiya: Biotechnological concepts for improving performance of wood fiber composites

Rajesh Koppolu: High-throughput processing of flexible functional devices

Ruut Kummala: Design of cellulose-based cell growth substrates

Diosángeles Soto Véliz: Unravelling mineral-cell interactions through the design of cell growth platforms

Contact Information

Visiting address:

Henrikinkatu 2 , Aurum 4th floor.

Postal address:

Paper Coating and Converting

Abo Akademi University

Henrikinkatu 2

20500 TURKU

FINLAND

Phone:

+358-2-215 31 (operator)

E-mail firstname.lastname@abo.fi or papercoating[at]abo.fi