Rajesh Koppolu

Laboratory of Paper Coating and Converting

E-mail: rajesh.koppolu@abo.fi

Co-operation partners: RISE – Research Institutes of Sweden, Sweden; Mid-Sweden University, Sweden; Tampere University of Technology, Finland; University of Oulu, Finland; CH-Polymers Oy, Finland; Omya International AG, Switzerland

The main objective of my research is to understand the requirements enabling roll-to-roll processing of complex functional materials on flexible substrates. The emphasis is on solution processing of functional materials into (patterned) thin layers utilizing high-throughput processes. The work aims at understanding (i) rheology, i.e., the flow properties, and structure formation of functional material-based dispersions and solutions, (ii) surface properties (e.g., surface roughness, wettability and adhesion) of the substrates and (iii) the compatibility between the functional materials and the substrates. This would allow the fabrication of novel devices on flexible substrates on a large scale, thus bringing down the manufacturing costs and making the processes economically viable.

Some of the applications we are working on are:

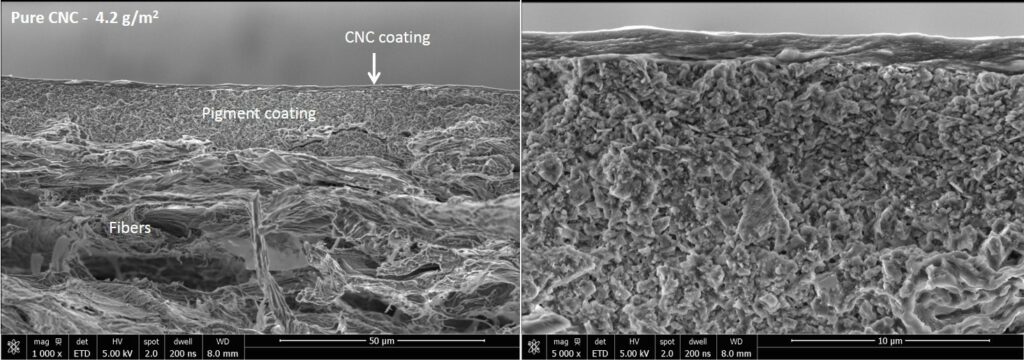

- Nanocellulose based barrier coatings for packaging applications

- Nano-graphite/graphene based conductive coatings on paper/metal foils for energy storage applications

- Batch and roll-to-roll printed drug delivery systems for personalized medicine

Peer-reviewed journal publications:

Kumar V., Koppolu V.R., Bousfield D.W. and Toivakka M. (2017) Substrate role in coating of microfibrillated cellulose suspensions. Cellulose, doi: 10.1007/s10570-017-1201-5.

Conference presentations:

Koppolu R., Kumar V., Toivakka M., Abitbol T., Swerin A., “Coatability of CNC suspensions in a high-throughput continuous process”, 2018 International Conference on Nanotechnology for Renewable Materials, Madison, Wisconsin, U.S.A. (2018).

Koppolu R., Toivakka M., Salminen P. and Preston J., “Sequential water absorption into linerboard”, Cellulose Materials Doctoral Students Conference, Graz, Austria (2017).