23.4.2024

Wood-derived 1D nanomaterials provide breakthrough in 3D printing technologies

Researchers at Åbo Akademi University and University of Turku recently announced that they have developed a highly functional bioink that will make it possible to 3D print life-like bone tissue models. One small, but essential, part of this success was the introduction of phosphorylated cellulose nanofibrils derived from wood biomass into the mix.

Cellulose and lignin are materials that are extremely abundant in nature. They are biopolymers that, among other things, provide trees and plants with their structural integrity. Driven by urgent need for bio-based products to replace petroleum-based counterparts in the societal sustainability transformation, these renewable biopolymers are considered to have a great potential to become cornerstones of the future bio-based economy.

Nanomaterials are materials that commonly measure less than 100 nanometers in at least one dimension. At the nanoscale, materials can exhibit unique properties not observed at larger scales. Nanofibrils, nanofilaments and nanotubes would be examples of 1D nanomaterials, that are constrained to nanoscale in two dimensions. 1D nanomaterials offer distinguished properties such as large specific surface area and high-aspect-ratio topography, i.e a structure with a significant difference in height or length compared to its width or diameter. This makes them useful when building complex 3D-structures.

Researchers at the Laboratory of Natural Materials Technology (NMT) and the Pharmaceutical Sciences Laboratory (PSL) at Åbo Akademi University recently made breakthroughs in the utilization of 1D nanomaterial derived from wood biopolymers in 3D printing technologies, and these nanomaterials are synthesized either through a bottom-up approach (nanomaterials built or synthesized from smaller components) to assemble lignin macromolecules as nanofilaments or through a top-down approach (removing or restructuring parts to create a smaller structure) to isolate cellulose nanofibers.

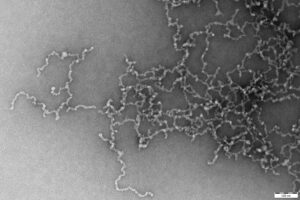

Lignin polymer is an aromatic complex. For the time being, it is extracted from pulp during paper production and often considered a sidestream. Lignin is considered the most important aromatic feedstock for production of biofuels, bioplastics and chemicals in the future bio-based economy. Lignin macromolecules commonly arranges themselves into zero-dimensional nanospheres, nanoscale in three dimensions. Taking advantage of the fact that ‘not all lignins are created equal’ in their botanical origins, researchers at the NMT were able to manipulate the lignin’s chemical structure and create photocrosslinkable lignin nanofilaments, which was then used as a highly efficient macromonomer together with polyethylene glycol diacrylate (a compound that can be used as a base for hydrogels) in high-precision fabrication of tough hydrogel via digital light processing (DLP) 3D printing, a printing technique that uses light to solidify the ink. The use of lignin nanofilaments also reduced the light scattering effect in DLP 3D printing, increasing precision. Lignin nanospheres, on the other hand, amplified the light scattering effect.

– Nanomaterials are all about surface. When you utilize a nanomaterial, you have to be able to access the surface. 1D nanofilament can be understood as slices of the nanospheres that are rearranged into long threads, making it possible to utilize a larger surface area of the material, says Academy Research Fellow at the PSL Xiaoju Wang.

– I think we are the only ones who have made lignin in this format, at least we are the only ones who have been reporting on it, she adds.

Bioprinting bone cells

Bioprinting works similar to traditional 3D printing in many ways, it creates three-dimensional structures layer by layer. The ink used in bioprinting however, contains living cells, usually within a hydrogel that also contains for example nutrients for the cells. Hydrogels are hydrophilic and the ones used for bioinks have properties similar to natural tissue and tend to be compatible with living systems.

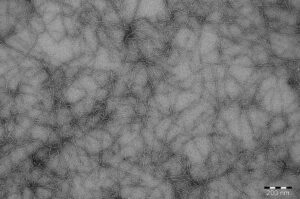

Aqueous two-phased emulsions (ATPE) have shown promise in many application areas. A classic ATPE consists of two water-soluble macromolecules of gelatin and dextran. Dextran is a polysaccharide, i.e a carbohydrate. Gelatin and Dextran create two distinct phases when mixed. It is biocompatible and suitable for formulating versatile bioinks. A stable ATPE has small droplets of one phase scattered throughout the other phase and this system ideally supports the formation of macropore within the macroscopic hydrogel, which is essential for cells living in the hydrogel to interact with each other and metabolize properly. However, the pristine ATPE of gelatin and dextran lacks the long-term stability and specific biofunctionality necessary for producing and maintaining bone tissue.

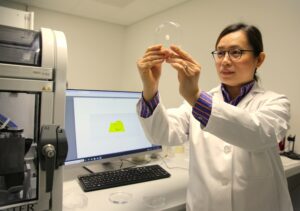

This is where the 1D cellulose nanofibrils created by Wang and her team come into the picture. The challenge of material stability was solved by the introduction of the phosphorylated cellulose nanofibrils (pCNF) into the mix. Small and extremely thin fibers, pCNF are isolated from wood tissue and functionalized with surface groups of phosphates during the nanosynthesis. The phosphates in the pCNF are also anticipated to function similarly to phosphorous groups found in natural bone cells and cartilage. The researchers concluded that pCNF are a multifunctional additive that can improve the flow behaviour of the ATPE bioink, while also making the hydrogel prints more stable and robust. More importantly, the pCNF facilitate growth and organization of living cells within the bioconstructs.

Calcium phosphate is an essential mineral for osteoblastic cells, a type of bone cells, and the phosphate in the pCNF is able to trigger the differentiation of the pre-osteoblastic cells in the hydrogel into proper osteoblastic cells. Pre-osteoblastic cells share similarities with stem cells, but they are more specialized towards bone cells. In a lab setting, the differentiation process would normally be triggered by chemically stimulating the pre-osteoblastic cells.

– Thanks to the distinguished characteristics of 1D nanomaterial, pCNF showed great network-forming ability even at low concentrations. This made them a game changer for our research, says Wang.

Future prospects for 1D nanomaterials

Pharmacological and diagnostic testing are possible areas of utilization for the newly developed bioink, regenerative medicine may be another possible future use. Next generation hydrogels suitable for wearable technology will also have to be tough and embedded with functionalities that are needed for monitoring physiological parameters, Wang believes.

– 1D sustainable nanomaterials definitely can contribute to these themes in different ways, she says.

Wang is certain that 1D nanofilament of lignin have additional utilization cases. The next step is to integrate conductivity into the system in order to facilitate the delivery of electrical stimulation to cells.

The realization of these innovations, and their final applications, requires interdisciplinary contributions. Material scientists like Wang play a crucial role in developing functional biomaterials that bridge the gap between research and the final implementation.

The two research papers, Evolution of Self-Assembled Lignin Nanostructure into Dendritic Fiber in Aqueous Biphasic Photocurable Resin for DLP-Printing and Bioprinting Macroporous Hydrogel with Aqueous Two-Phase Emulsion-Based Bioink: In Vitro Mineralization and Differentiation Empowered by Phosphorylated Cellulose Nanofibrils, produced by the teams at Åbo Akademi University and University of Turku were published in Advanced Functional Materials.